Safety & Lifting Device Certification

16+ Years of Experience | Quality Engineering | 3D Drone Mapping Techniques

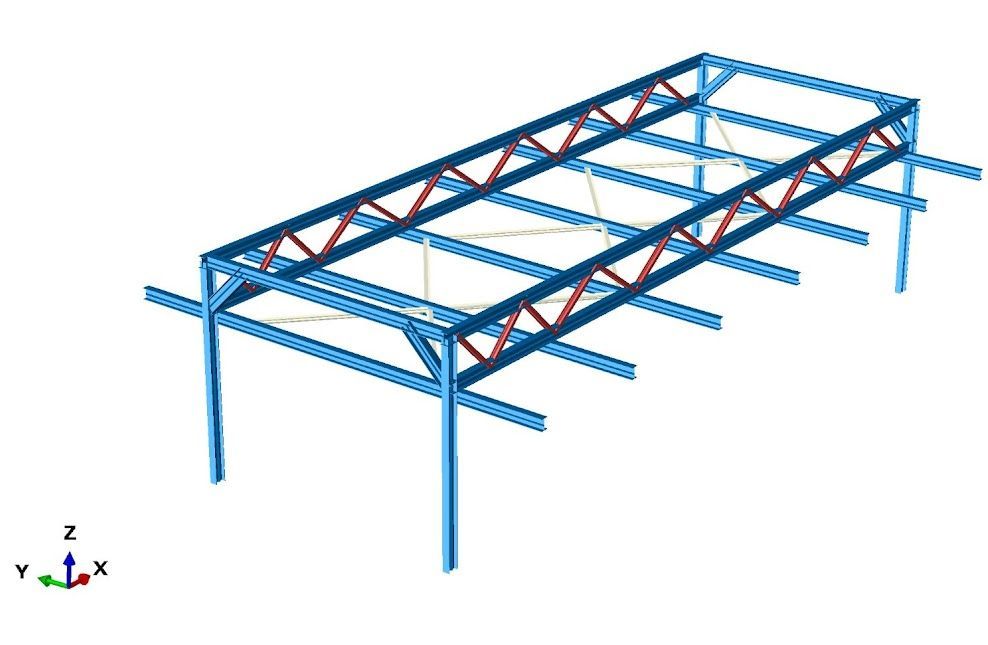

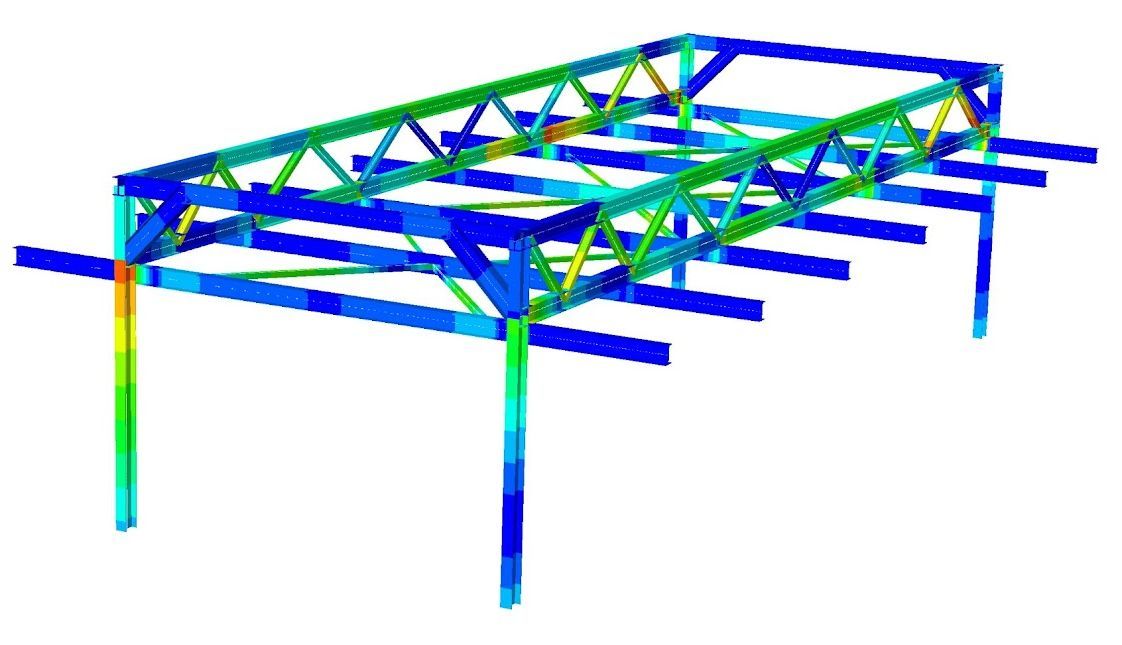

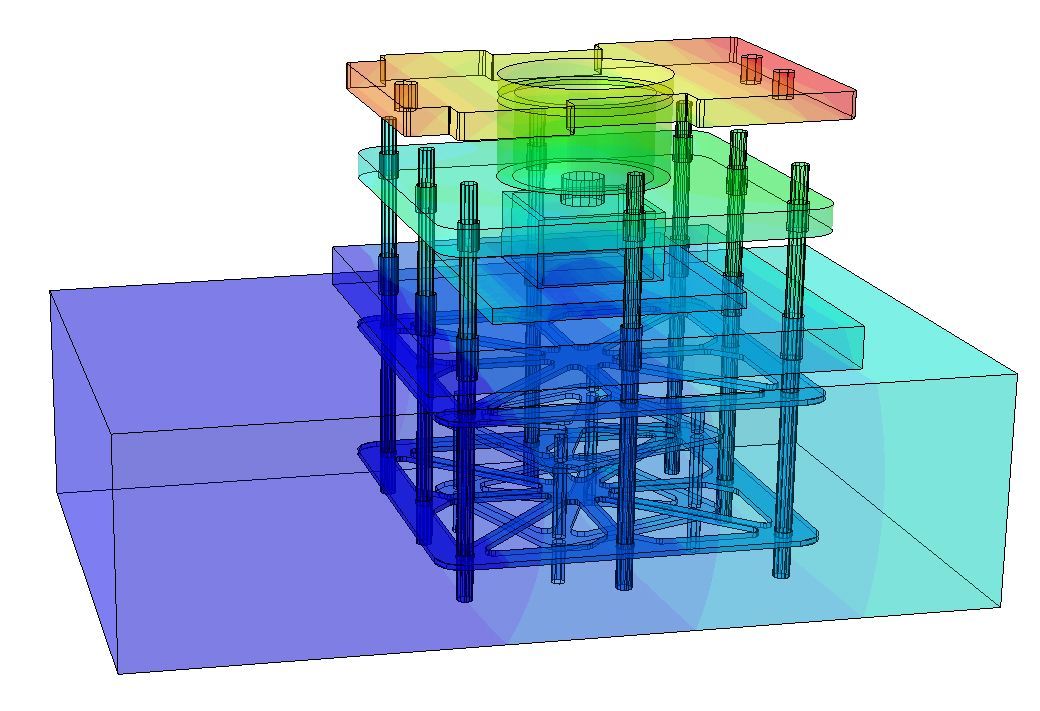

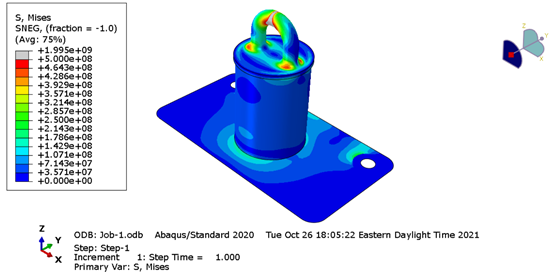

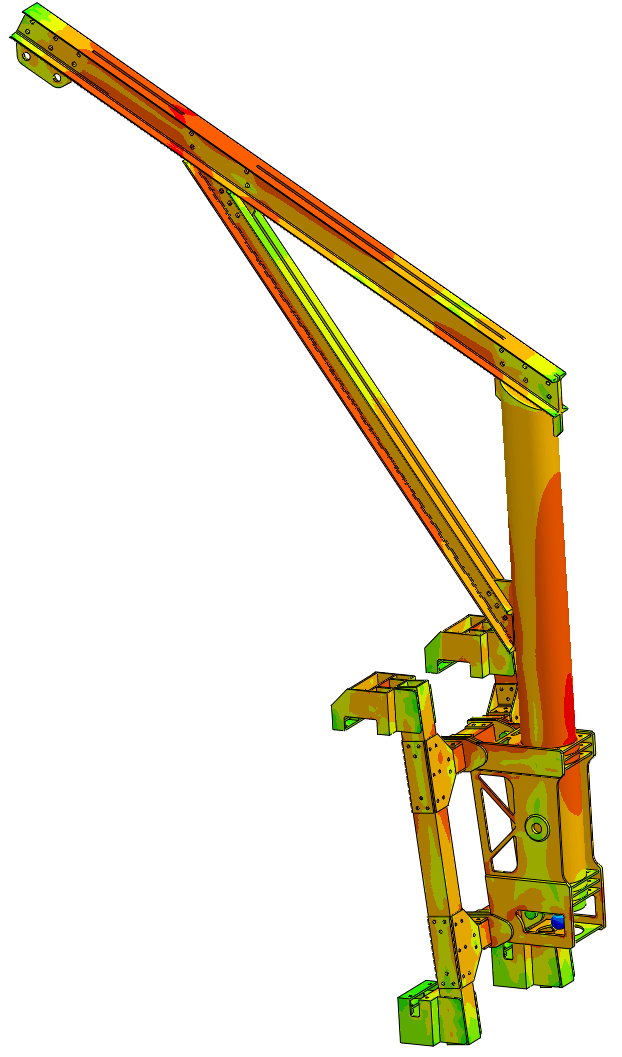

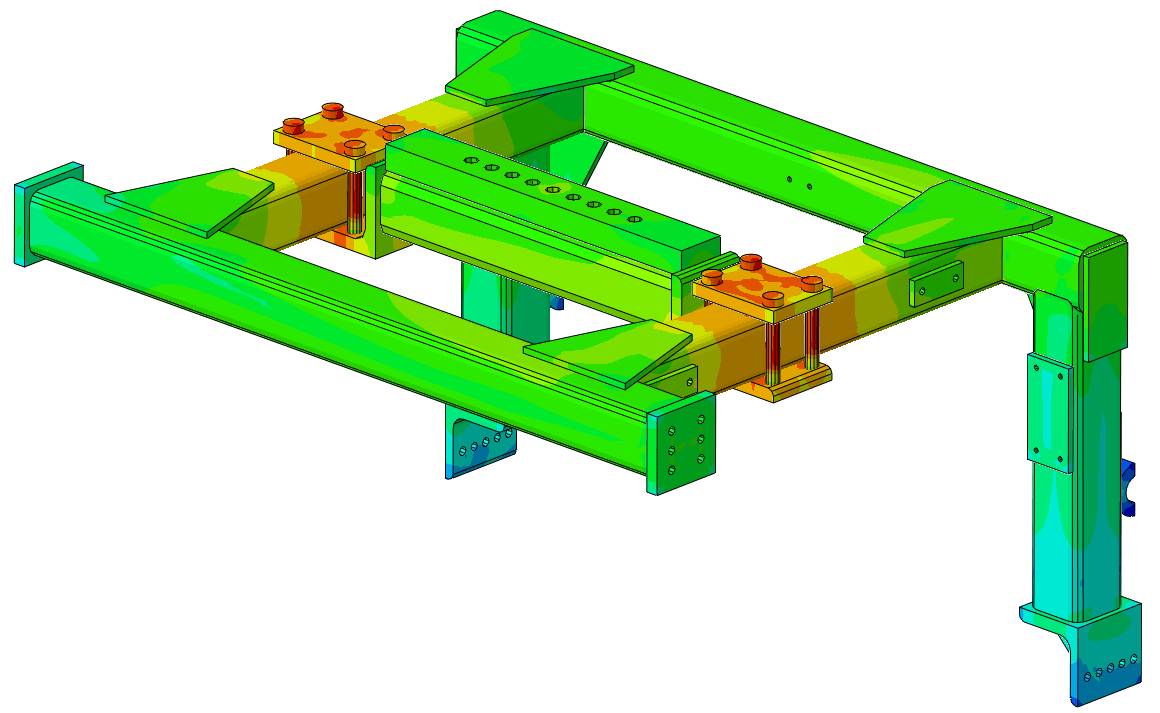

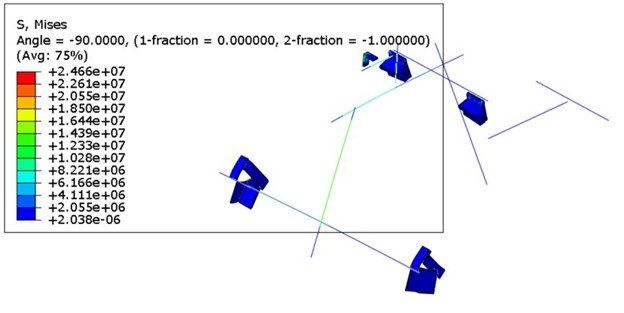

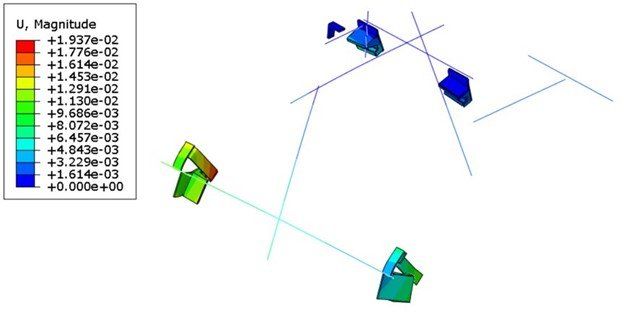

Are you seeking accurate and reliable Finite Element Analysis (FEA) services for your engineering needs? Look no further. Our team of skilled professionals specializes in utilizing Abaqus, a powerful and industry-leading software, to provide top-notch FEA services. With Abaqus, we can conduct comprehensive simulations and analyses to assess the structural integrity, performance, and safety of your designs. Whether you need stress analysis, vibration analysis, thermal analysis, or any other FEA application, we have the expertise to deliver precise and detailed results. Our services are tailored to meet your specific requirements and ensure compliance with industry standards and regulations. By entrusting us with your FEA needs, you can benefit from our cutting-edge technology, extensive experience, and commitment to delivering accurate and actionable insights. Contact us today to unlock the full potential of Abaqus FEA and elevate the quality of your engineering projects.

ANSI BTH30 is a widely recognized standard developed by the American National Standards Institute (ANSI) that provides guidelines for designing, operating, and maintaining below-the-hook lifting devices. The standard outlines best practices for ensuring the safety and efficiency of lifting operations, specifically focusing on the equipment and attachments used to lift loads. ANSI BTH30 establishes requirements for factors such as load rating, materials, structural design, and inspection procedures. It also addresses various types of lifting devices, including hooks, shackles, and lifting beams, offering recommendations for their proper selection, installation, and use. By adhering to the ANSI BTH30 standard, industries can enhance safety, reduce the risk of accidents, and promote consistent and reliable lifting practices in compliance with industry regulations.

Conducting a finite element analysis (FEA) of a lifting device to OSHA (Occupational Safety and Health Administration) standards involves utilizing advanced computer simulation techniques to assess the structural integrity and performance of the device under various loading conditions. The analysis aims to ensure that the lifting device meets OSHA's stringent safety requirements, minimizing the risk of failure and potential hazards in lifting operations. Engineers use FEA software to model the lifting device's geometry, materials, and operating conditions, simulating its response to applied forces, stresses, and deformations. By comparing the results against OSHA's guidelines, such as load capacity limits, factor of safety requirements, and stress concentration limits, engineers can identify potential design flaws, weak points, or areas of concern. This analysis allows for modifications or reinforcements to be made to the lifting device to ensure compliance with OSHA standards and enhance its safety and reliability in real-world lifting scenarios.

Analyzing fall arrest devices using finite element analysis (FEA) to OSHA, ASME, and ANSI standards involves employing advanced computational techniques to evaluate the structural integrity, performance, and safety of these devices in compliance with these recognized industry standards. FEA allows engineers to create a virtual model of the fall arrest device, simulating its response to various loading conditions and forces associated with fall events. By applying the specific requirements outlined by OSHA, ASME, and ANSI, such as load capacity, factor of safety, and stress limits, engineers can assess the device's ability to withstand the forces experienced during a fall and ensure it meets the stringent safety guidelines. FEA helps identify potential weak points, stress concentrations, and areas of concern in the device's design. Through this analysis, engineers can make necessary modifications, optimizations, or reinforcements to the fall arrest device to ensure it complies with these standards and provides reliable and effective fall protection in accordance with OSHA, ASME, and ANSI requirements.

Share On: